Vision-Guided Evolution

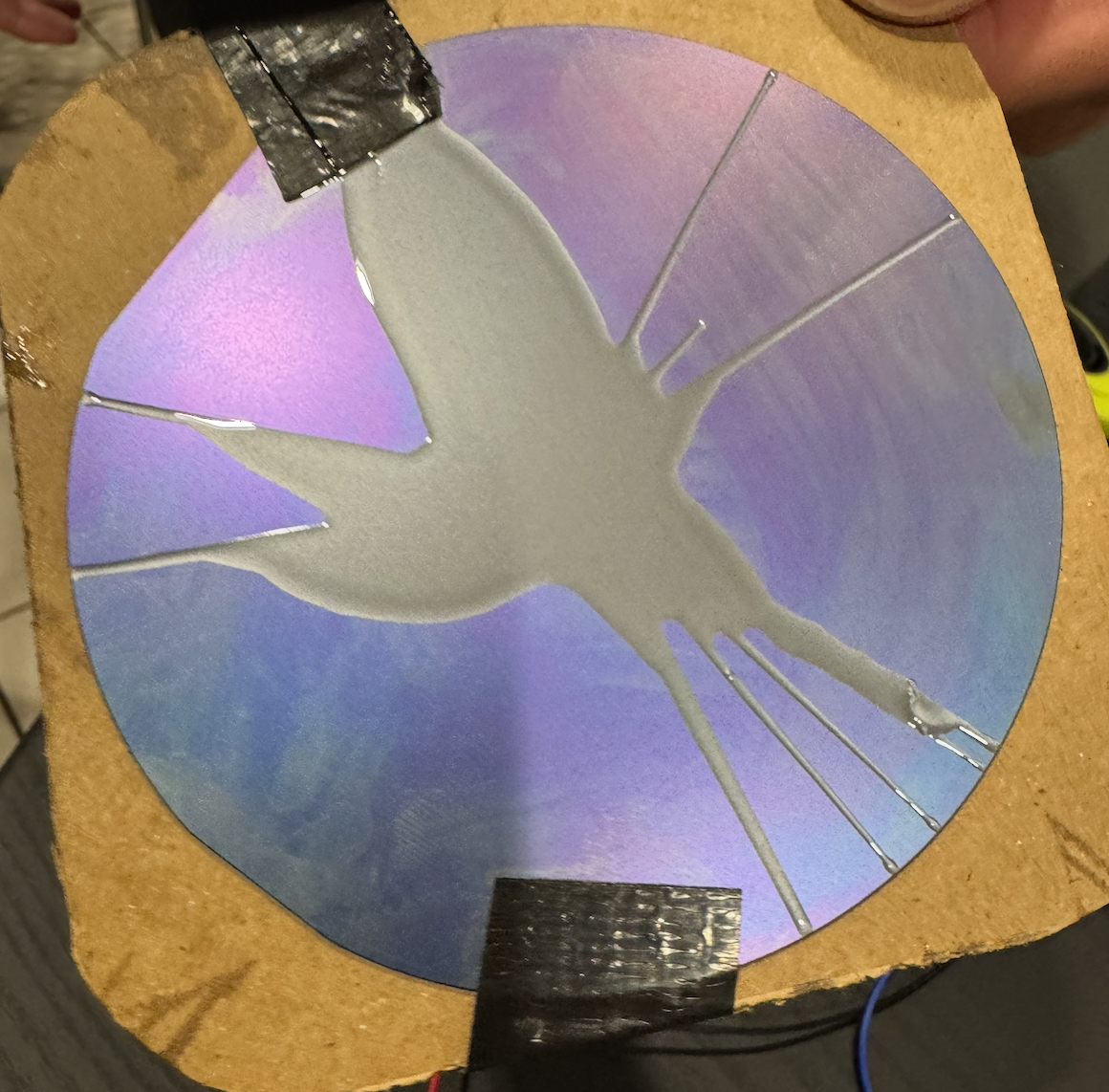

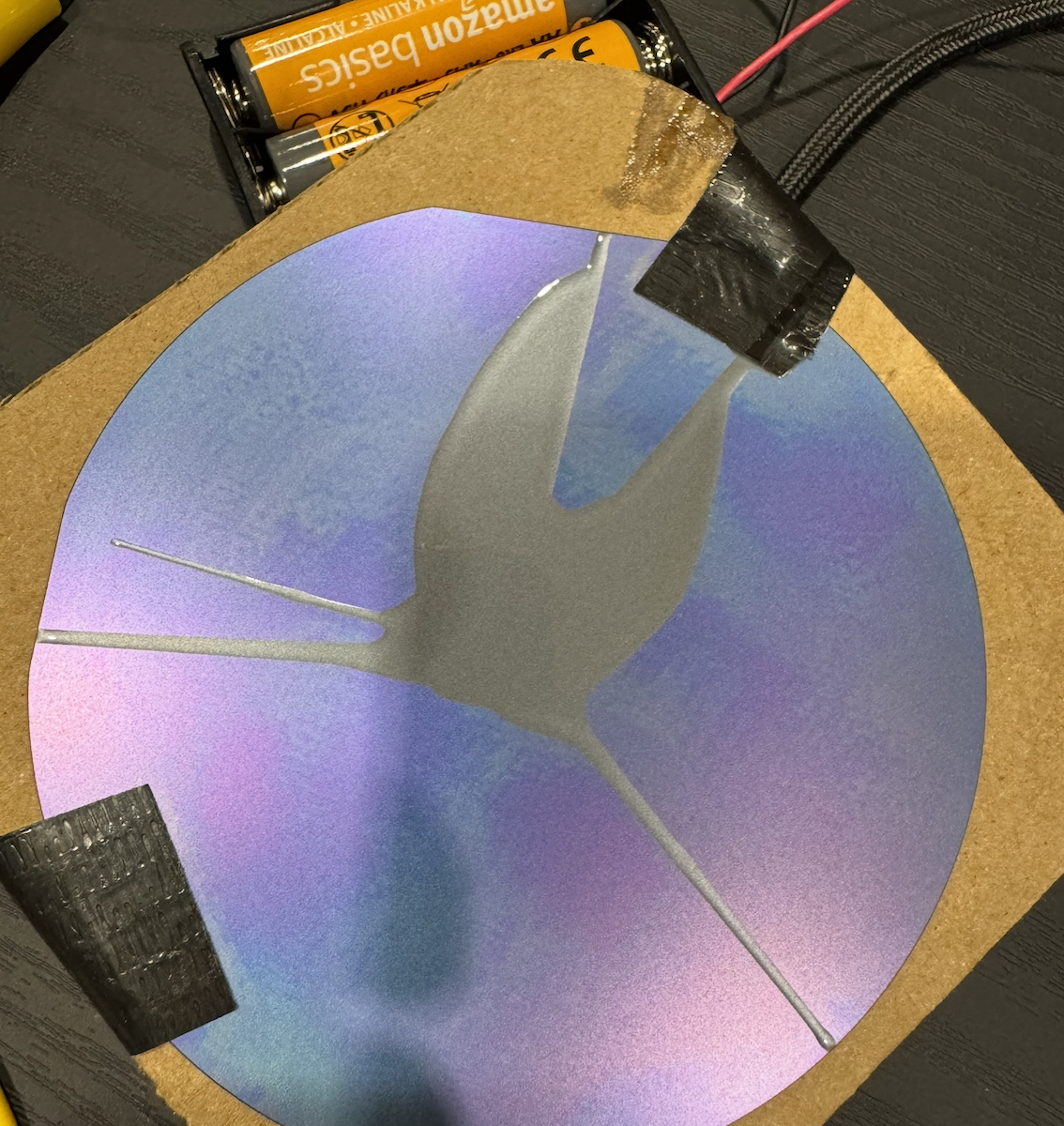

A vision model scores each wafer on uniformity, coverage, and defects — producing the fitness signal that drives our evolutionary optimizer. Here we show how it evaluates spin-coated wafers and discovers the optimal spin speed window for UV resin.

You are an expert fabrication quality evaluator. You will be shown a photo of a silicon wafer after spin coating with UV resin. Score the wafer on the following criteria (0.0–1.0): - **uniformity**: How evenly is the resin distributed across the wafer surface? - **coverage**: What fraction of the wafer has a thin, usable coating? - **defects**: Inverse defect score (1.0 = no defects, 0.0 = severe defects) Then compute an **overall_fitness** as a weighted average. Explain your reasoning step by step.

Evolutionary Insight: Finding the Optimal Spin Window

After evaluating three wafers across a range of spin speeds, the vision model reveals a non-monotonic relationship: too slow (6V) leaves thick, unusable resin, but too fast (12V) causes turbulent spreading and center re-accumulation. The sweet spot sits around 9V (~2700 RPM), where centrifugal force is strong enough to overcome the resin's viscosity but not so aggressive that it creates flow instabilities. This is characteristic of UV resin — its higher viscosity compared to standard photoresist demands a narrower RPM window. This fitness signal directly shapes the next generation of experiments: the evolutionary optimizer concentrates its search around the 9V–11V range, pruning both the low-speed and high-speed regions that produce defective coatings.

Fitness Progression by Spin Speed

Future Work

Directions we're exploring to extend autonomous fabrication beyond single-parameter spin coating.

Multi-Step Recipes

Extend the evolutionary search to optimize full fabrication recipes — multi-layer deposition, bake profiles, development times — not just single-parameter spin coating.

Advanced Sensors

Integrate in-situ thickness sensors (ellipsometry, spectrometry) and real-time defect detection cameras for richer fitness signals beyond post-process imaging.

Multi-Objective Optimization

Evolve across competing objectives simultaneously — throughput vs. uniformity vs. cost — using Pareto-front evolutionary strategies.

Foundation Model Scoring

Replace prompt-engineered vision scoring with a fine-tuned multimodal model trained on thousands of labeled wafer images for more precise and consistent fitness evaluation.