Autonomous

Nanofabrication

Closing the loop between AI and hardware. Differentiable simulation, evolutionary optimization, and autonomous physical fabrication — unified in a single platform.

Lithography Simulation

We use differentiable lithography simulation and gradient descent to optimize photomask designs. Standard optimization often merges features that should be separate. Our improved loss with gap preservation keeps features separated even when diffraction tries to fill in narrow gaps.

Lithography Pipeline — TorchResist

Live Optimization — Standard vs Improved

L2(aerial, target) + TV regularization + fidelity — features merge freely

+ Gap preservation + connectivity + edge weighting + mask biasing

IOU Convergence

L2 Loss Convergence

Live Fabrication Feed

Monitor the autonomous fabrication chamber in real time. The system captures high-resolution imagery for closed-loop quality assessment.

Awaiting camera connection...

Open /broadcast on iPhone to stream

Chamber Status

Fabrication Control Panel

Define the material and parameter search space. The evolutionary optimizer explores these ranges to find the optimal process parameters that maximize pattern fidelity.

Material Selection

Process Parameters — Search Space

The evolutionary optimizer will search within these ranges

Execution Log

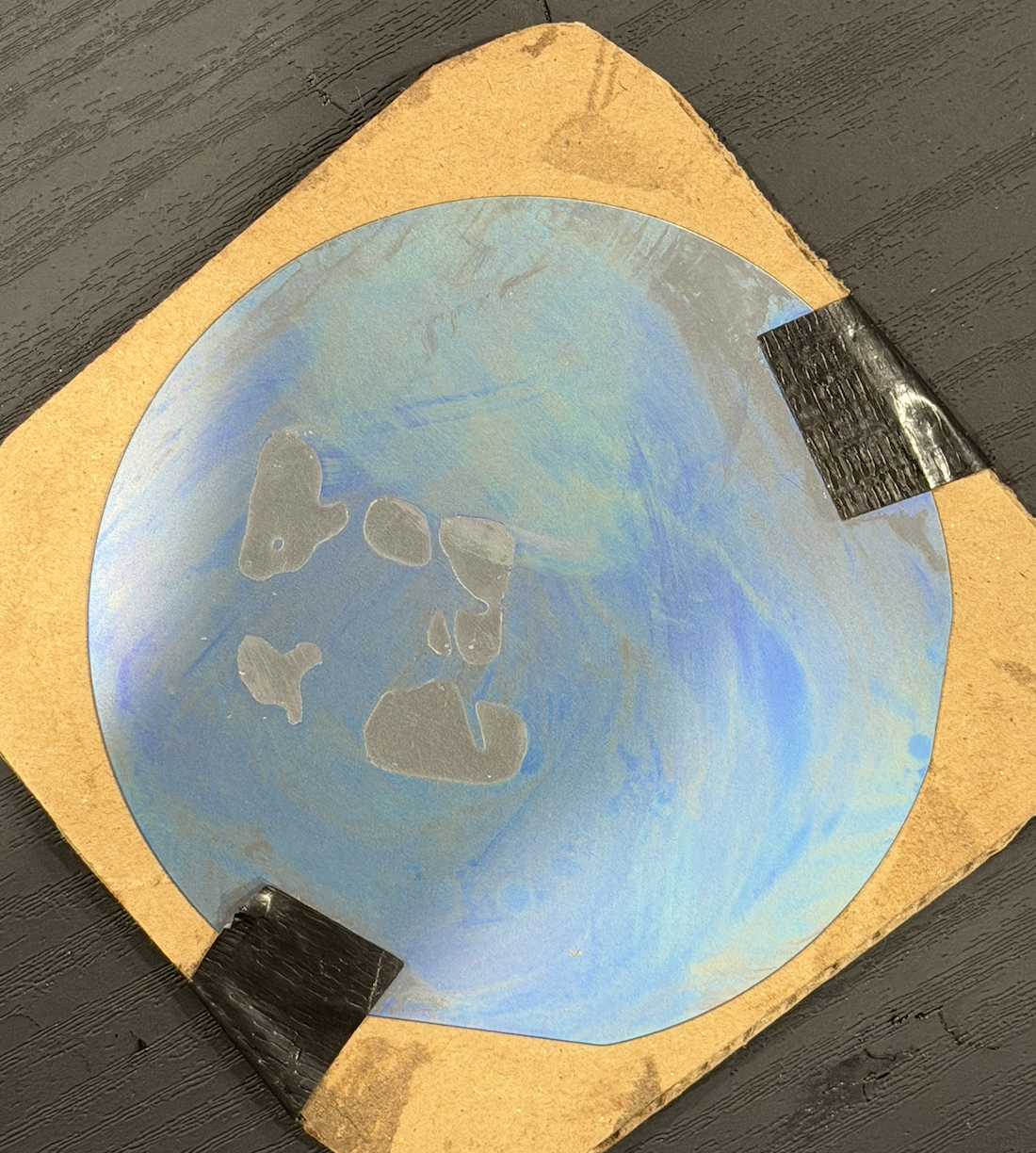

Evolutionary Search

Real fabrication experiments with photos. Each node is a physical wafer produced with different parameters. The optimizer suggests the next experiments to run based on prior results.

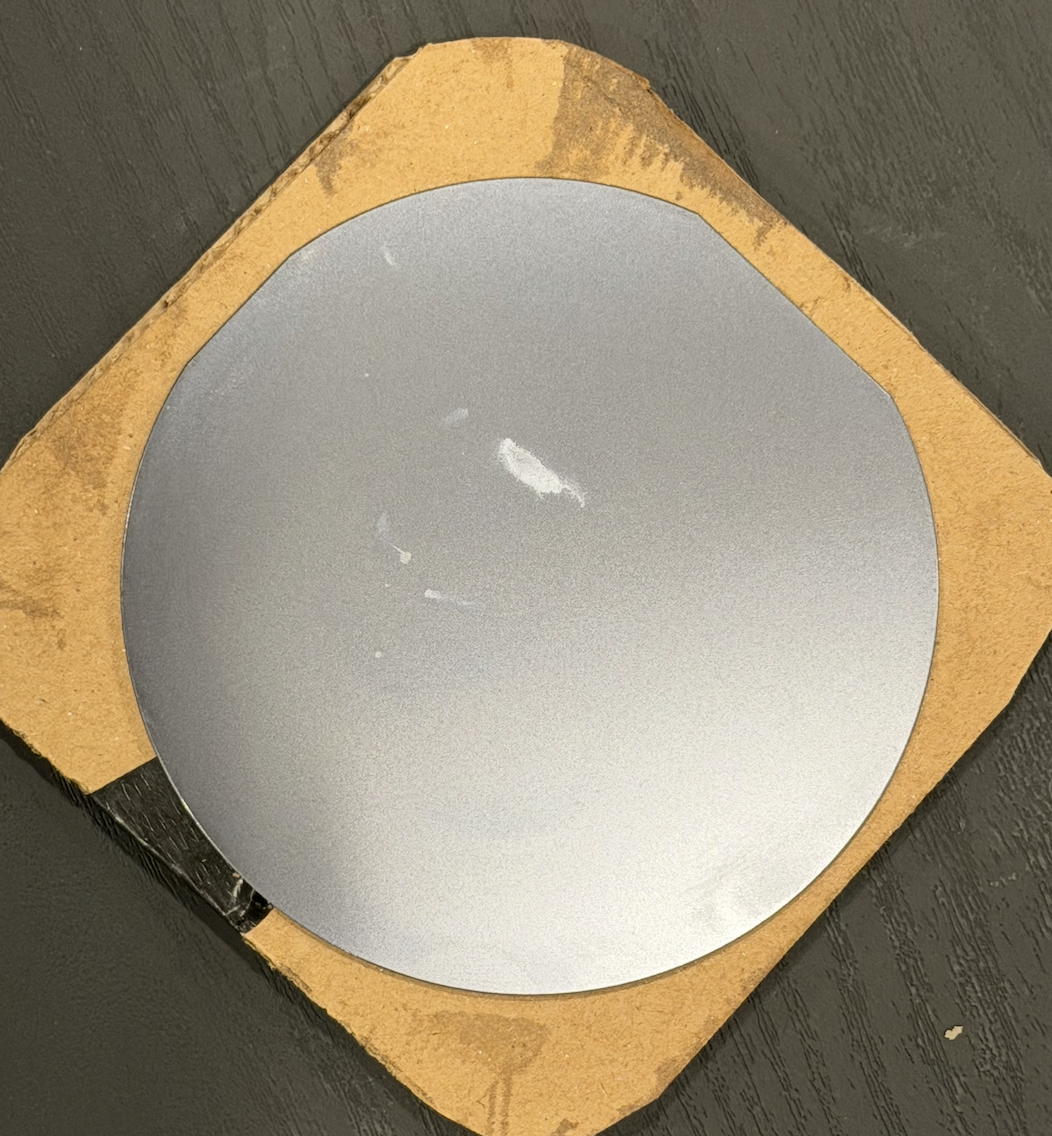

Reference Mask

Target pattern to reproduce on wafer

Parameter Space

Best Experiment

Suggested Next

Parameters selected by evolutionary optimizer based on fitness gradient near best result

Technical Architecture

A closed-loop system unifying differentiable simulation, autonomous hardware, and evolutionary optimization.

RL Environment

The fabrication process is modeled as a Gymnasium-compatible RL environment. States encode current process parameters and observation images; actions adjust spin speed, exposure, and mask geometry; rewards measure pattern fidelity via EPE and CD metrics.

Evolutionary Hill Climbing

Built on OpenEvolve's MAP-Elites framework with island-based parallel evolution. The system maintains a diverse population grid and uses LLM-guided mutations alongside standard evolutionary operators for efficient parameter search.

Modular Material System

The platform supports pluggable material profiles — from standard UV resins on glass substrates to PCB photoresists on silicon. Each material module encodes spin curves, exposure response, and development kinetics.

Sim-to-Real Transfer

TorchResist's calibrated resist model bridges the simulation-reality gap. Calibration data from physical experiments continuously improves the simulator, creating a virtuous feedback loop between digital and physical optimization.

Research & Bibliography

Key papers and resources that underpin this platform.

TorchResist: Differentiable Lithography Simulation for Inverse Mask Design

Chen, Y., Liu, X., Zhang, W., et al.

LithoSim: A High-Fidelity Computational Lithography Simulator with GPU Acceleration

Wang, H., Li, J., Chen, S., et al.

DUV Multi-Patterning Optimization via Reinforcement Learning

Park, S., Kim, D., Lee, M., et al.

Monolithic 3D Integration: EDP Co-Optimization for Advanced Logic and Memory

Zhang, L., Huang, R., Thompson, A., et al.

OpenEvolve: Evolutionary Coding with Large Language Models

Lehman, J., Gordon, J., Jain, S., et al.

Vision

Autonomous nanofabrication as infrastructure for the next generation of computing — where AI and hardware co-evolve.

AI Scaling Bottleneck

The semiconductor industry faces a fundamental challenge: the AI systems designing next-gen chips run on current-gen hardware. Breaking this circular dependency requires autonomous fabrication that can iterate faster than human-in-the-loop processes.

Fabrication as Optimization

We reframe nanofabrication as a black-box optimization problem. Instead of manual recipe tuning, we let evolutionary algorithms and differentiable simulation jointly discover process parameters that maximize pattern fidelity.

Modular Materials

Our platform is material-agnostic. Swap substrate types, photoresists, and exposure sources through a pluggable material system. Each module encodes the physics of a specific material stack.

Virtuous Cycle

Better AI designs better chips. Better chips run better AI. Our platform accelerates this cycle by removing the human bottleneck in the fabrication-optimization loop, enabling rapid iteration from simulation to silicon.

TreeHacks 2025 — Stanford University

AI-Driven Closed-Loop Fabrication and Process Discovery